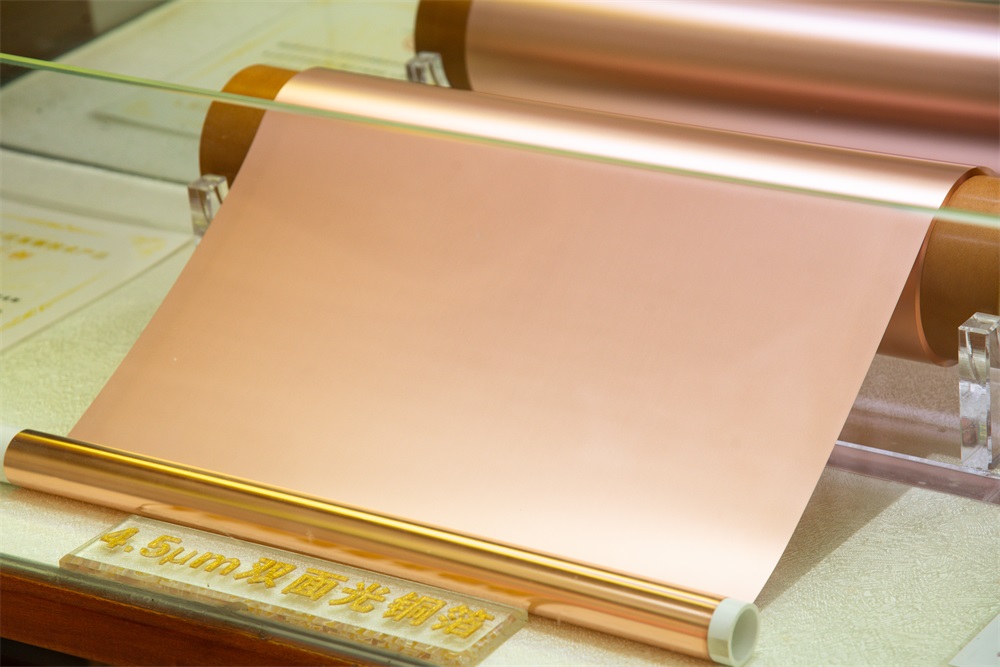

double-sided light copper foil

Double-sided bright copper foil is produced through a special process on the M side, transforming its rough surface into a bright one. The foil, in roll form, can be cut into rolls with widths ranging from 100mm to 1480mm. The double-sided bright electrolytic copper foil is remarkably uniform in thickness, and its crystal structure appears fine and dense when observed under a scanning electron microscope. It serves as an excellent carrier for lithium battery anode materials.

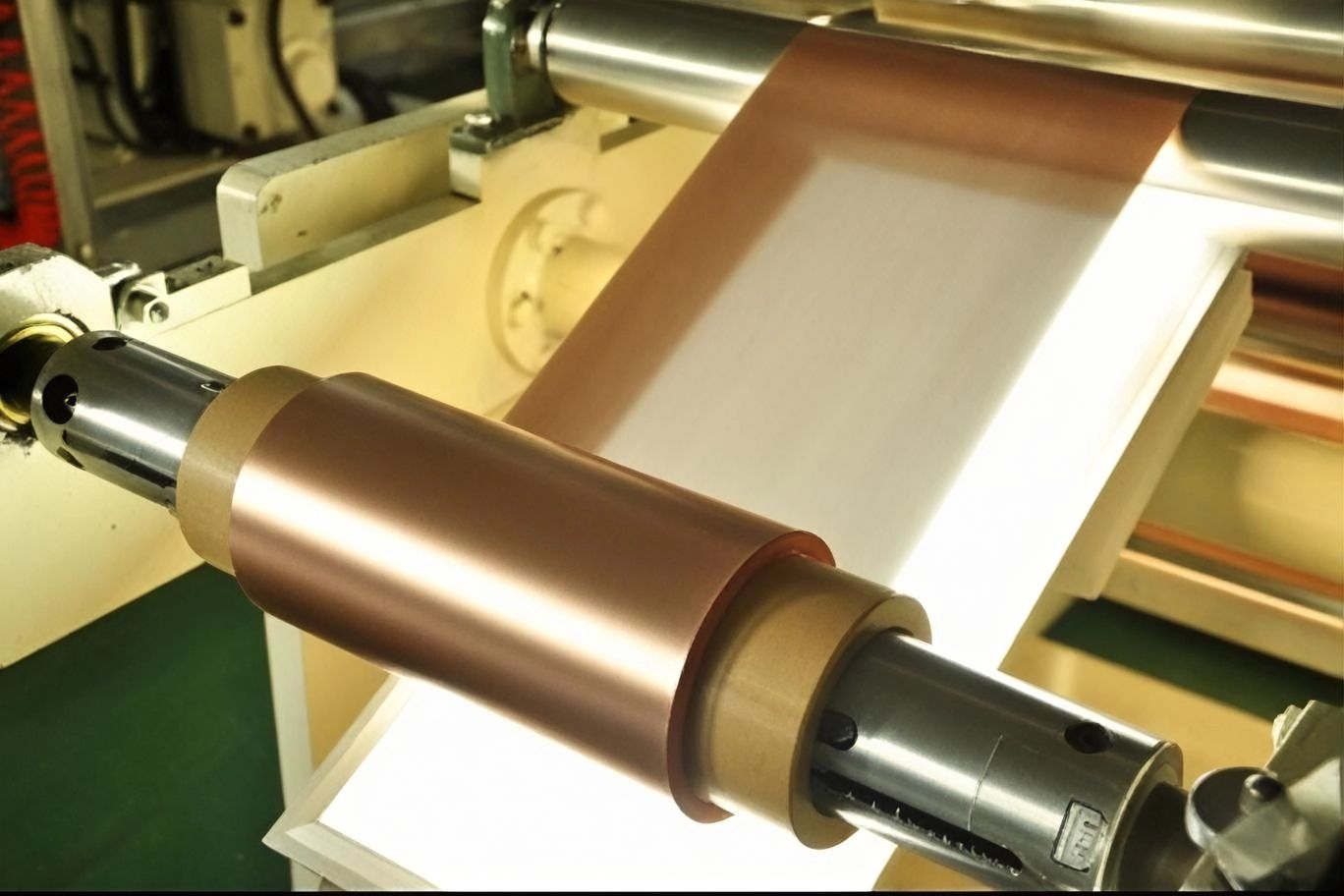

The company's 3.5μm ultra-thin high-end copper foil can reach a single roll length of over 40,000 meters, with a thickness only one-twentieth of the diameter of a human hair. Its overall technical level is internationally leading, and it can increase the energy density by about 10% when applied to batteries with the same unit volume.